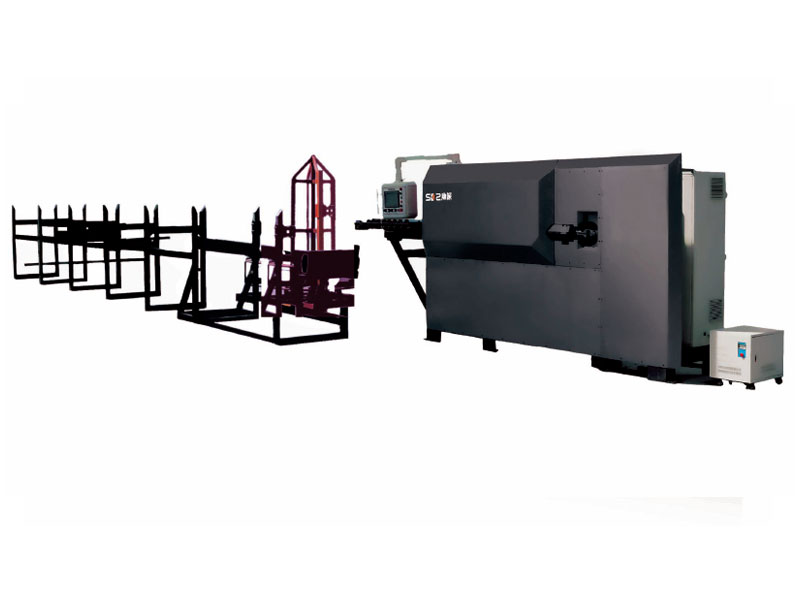

Stirrup Bender uses a new type of reducer, large gear, pinion, curved disk surface, etc. The two-stage brake motor and reducer are combined to reduce the speed. The meshing of the small gear and the large gear is a two-level reduction. The large gear always drives the curved disk surface. During the rotation, a middle shaft hole and a plurality of bending shaft holes are provided on the curved disk surface. The intermediate shaft can be replaced for easier maintenance. The intelligent control is adopted. As long as it is used in the processing of cold rolled ribbed steel bars, hot-rolled tertiary steel bars, cold-rolled round steel bars and hot-rolled round steel bars, etc., it has low failure rate, low noise, stable performance, and so on. Only two people are required to operate, and the processing efficiency of one device is equivalent to 3 to 5 times of manual labor.

Common faults of CNC straightening and bending machine are as follows:

(1) Turning the cutter head. This is a relatively simple fault. Just adjust the moving knife induction switch.

(2) The steel bars are not straight after the tube is out, and the problem of ups and downs often occurs. At this time, the lower group and the upper group of rear wheels should be adjusted separately and pushed in the opposite direction.

(3) When bending a double tendon, there is a tendency for the outer steel bar to fall off the bending axis, and the corresponding countermeasure at this time is to reduce the bending speed.

When using Stirrup Bender, pay attention to maintaining the pressure, generally 4MPa is appropriate, too high may cause deformation of the reinforcement or equipment damage.

So what should you pay attention to when operating Stirrup Bender to reduce operation failure? Don’t worry, the following Low Speed Straightening Cutting Machine Manufacturer will come to tell you.

Operating procedures and matters needing attention:

First, check whether the mechanical performance is good, the table and the bending machine table are kept horizontal; and various mandrel tool stops are prepared.

2. When bending high-hardness or low-alloy steel bars, change the standard large diameter according to the mechanical nameplate and replace the corresponding mandrel. Wide application: The equipment adopts CNC servo control system, which can automatically complete the processes of steel bar straightening, sizing, bending hoop, cutting, etc., can bend large 16mm steel bars, and continuously produce any flat shape products.

3. During operation, insert one end of the steel bar that needs to be bent into the gap provided by the turntable, and the other end should be fixed against the fuselage and pressed by hand. Check the fuselage to ensure that it is installed on the side that blocks the steel bar.

4. Install the mandrel, forming shaft, iron shaft or variable bracket according to the diameter of the processing steel bar and the requirements of the bending machine. The diameter of the mandrel should be 2.5 times the diameter of the steel bar.

5. Check the mandrel, the stopper, the turntable should be free of damage and cracks, the protective cover is fastened and reliable, and can be operated only after confirming the normal operation of the empty machine.

6. It is strictly forbidden to replace the mandrel, change the angle, and adjust the speed during operation, and do not refuel or remove it.

7. When bending steel bars, it is strictly forbidden to process the steel bar diameter, the number of bars and the mechanical speed exceeding the mechanical requirements.

The above is the correct operation method of Stirrup Bender introduced by the Wire Bending Machine supplier. I hope it can help everyone.

CN

CN