Stirrup bender is designed to complete straightening,bending and cutting on one machine. Coil is the prefer raw material choice .The machine is capable of providing our clients the most accurate cutting , straightening, bending and high effect, which is widespread used in high speed railway, bridge, real estate, reinforcing steel processing factories , etc.

Model | KZ16AX | |

Raw material | coil | |

Production capacity | Single wire | φ8 -16 (mm) |

Double wire | φ8-13 (mm) | |

Max. bending angle | ±180°(double direction) | |

Max. bending speed | 900 (°sec) | |

Max. pulling speed | 110 (m/min) | |

Max. Length of the stirrup side (diagonal) | 2500 (mm) | |

Min. length of the stirrup side | 150 (mm) | |

Length tolerance | ± 1 (mm) | |

Bending tolerance | ±1° | |

Average air-compressed consumption | ≥0.6 | |

Total power rate of loading machine | 57.5(kw) | |

Voltage | 400(V) – 50 (Hz) | |

Overall machine weight | 5500(Kg) | |

Overall dimension | 6100 *1600 * 2210 (mm) | |

Stirrup Bending Machine Product Advantages

1. Large processing range, can be bent forward and backward;

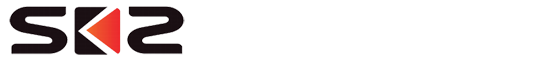

2. Fixed cutter can be used on both sides to improve service life and reduce cost;

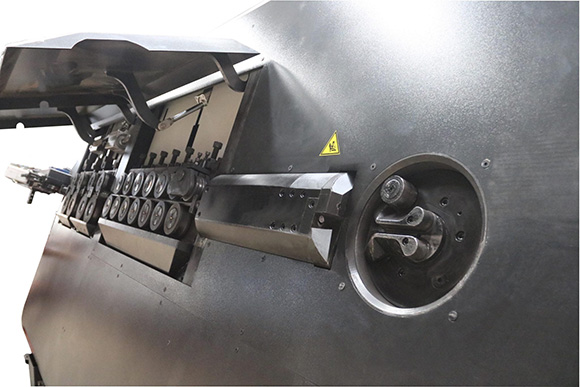

3. Configure automatic feeding mechanism, saving time and effort;

4. Single Wire Diameter 8-16 mm, double wires 8-13 mm; precision and fast machining;

5. Stirrup Bending Machine has high precision of PLC control, LCD display is easy for operating, have mighty graphics library, it is able to communicate with management software;

6.SKZ of wire bending machine has been sold more than 2000 pieces around the world.

Steel Bending Machine Principle

The wire rod steel bar is firstly conveyed to the bending mechanism of the steel bar bending machine after horizontal straightening and vertical straightening, and then conveyed to the bending mechanism of the steel bar bending machine, and the flexible bending of the wishing elbow is controlled by the PLC program to quickly realize the bending forming process of the various shapes of the stirrups. Then, the finished product of the stirrup is cut by the steel cutting mechanism. The entire process is fully automated and requires no human intervention.

CN

CN