The flat working structure can realize automatic feeding and unloading, and the movable receiving device can be more standardized. The complete set of curved columns can be arranged to meet the processing of different steel bars, free to replace and easy to operate.

| Model | KZW50X |

| Moving speed(m/nin) | 40 |

| Bending speed(r/min) | 6-8 |

| Bender Qty. | 2 |

| Mobile bender move method | Automatic |

| Power consumption(Kw/h) | 10 |

| Min. bending side length (distance between 2 mandrels) | 1200 (mm) |

| Accuracy of bending angle | ±1° |

| Conveyor load capacity(KG) | 1000 |

| Total power(KW) | 30 |

| Total weight | 8.8T |

| Diameter(mm) | 10 12 14 16 20 25 28 32 40 50 |

| Bending bars no0 | 7 6 5 5 4 3 3 2 1 1 |

STRUCTURE & CHARACTERS

1.STORAGE TABLE WITH ROLLER CONVEYOR

- Maxiumu bar length 12m.

Maximum carrying capacity 1,000Kg.

Roller conveyor, motor drive.

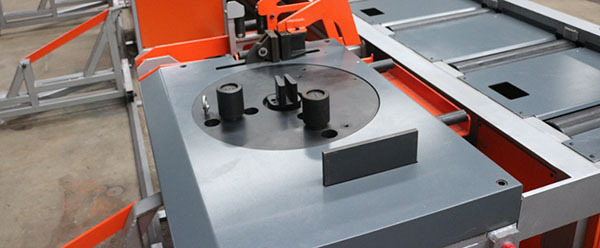

2.fixed and mobile bender

- 1 mobile bender

1 fixed bender

Servo motor driven

Pneumatically operated lifting device, delivery straight bars to bending mandrel and transfer shaped bars to storage rack.

Pneumatically operated clamp device will fix the steel bars while bending.

Shaped bars storage rack.

3.CLAMPING AND STOCKING UNIT

- Pneumatic clamping and uplifting unit

Movable collecting stock

4.ELECTRONIC CONSOLE

- Touchable screen display.

PLC control system.

The data base can store more than 100 shapes.

CN

CN